FLUX Beam Air 2.0 Filter

You Save 60%

Compatible with FLUX laser cutter machines: Beamo, Beambox & Beambox Pro click here.

Filters for the Flux HEXA will be announced soon.

FLUX Beam Air – Laser-Cutting Workspace Air Filter

The FLUX Beam Air is a dedicated exhaust filtration unit designed for laser cutters and engravers. It captures fumes, odours, and fine particulates produced during laser cutting or engraving, providing a cleaner, safer workspace. Compact, quiet, and fully compatible with FLUX machines, it ensures your environment stays comfortable and compliant with air-quality needs.

Compact, Practical Installation

With a footprint of approximately 490 × 260 × 470 mm and a weight of around 17 kg, the Beam Air fits neatly beside most desktop laser cutters. Its flexible 100 mm inlet hose connects directly to FLUX machines such as the Beamo, Beambox, and Beambox Pro, while durable casters make it easy to reposition as needed. Despite its compact form, the brushless motor provides strong airflow with low noise levels—ideal for classrooms, studios, or workshops.

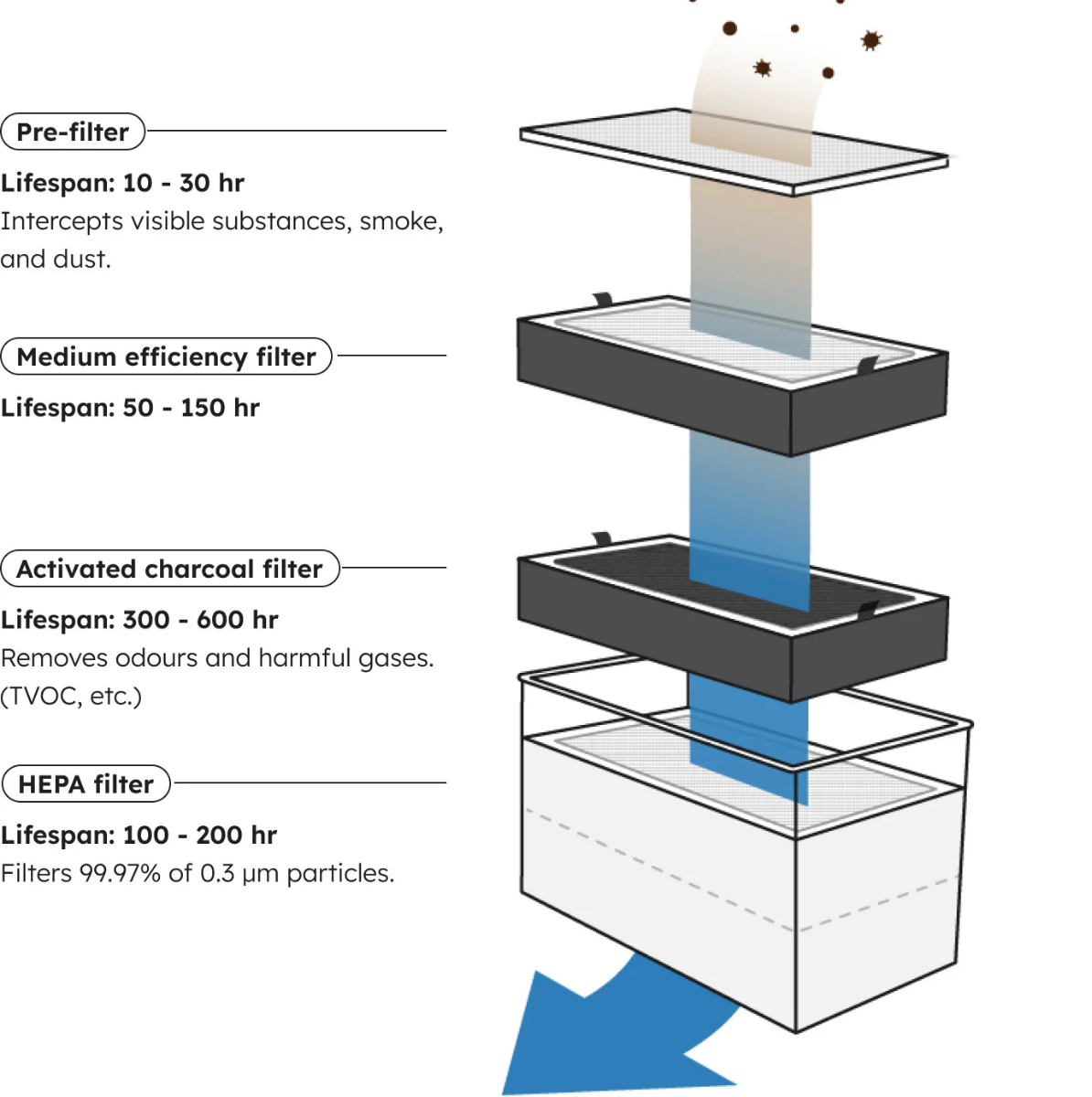

The unit connects to compatible FLUX lasers via USB-B for automatic start and stop control, with a manual knob for adjusting fan speed to balance airflow and noise. For consistent performance, filters should be replaced regularly—typically every 10 to 30 hours for the pre-filter, 50 to 150 hours for the medium filter, 100 to 300 hours for the HEPA filter, and 300 to 600 hours for the carbon layer—helping maintain optimal suction and clean air output.

Filtration System & Workflow Benefits

The Beam Air uses a four-stage filtration system to remove dust, gas, and odour generated by laser processing:

- Pre-filter: Captures larger particles of dust and debris.

- Medium-efficiency filter: Traps finer particles from engraving and cutting processes.

- Activated carbon filter: Absorbs odours and volatile organic compounds.

- HEPA filter: Removes microscopic particles down to 0.3 µm for cleaner exhaust air.

Why this matters: Working with wood, acrylic, or leather produces smoke and vapours that can linger in enclosed rooms. Beam Air effectively removes these by-products, helping you maintain clear air, prevent dust re-circulation, and improve long-term reliability of both your laser optics and workspace ventilation setup.

Keeping filters fresh prevents clogs, maintains suction power, and ensures continued removal of fumes and fine particles for optimal performance.

| Tech Specs | TECH SPECGeneral Specs

|

|---|