How to Design for Vacuum Forming and Mould Making

How to Design for Vacuum Forming and Mould Making

Before you get started using your Mayku FormBox, there are a few things you’ll need to understand about vacuum forming and tips that will help your product look much better. As it happens with 3D printing, there are some best practices that you should know before you start designing. You can design from scratch or adapt an existing 3D design that you already have access to.

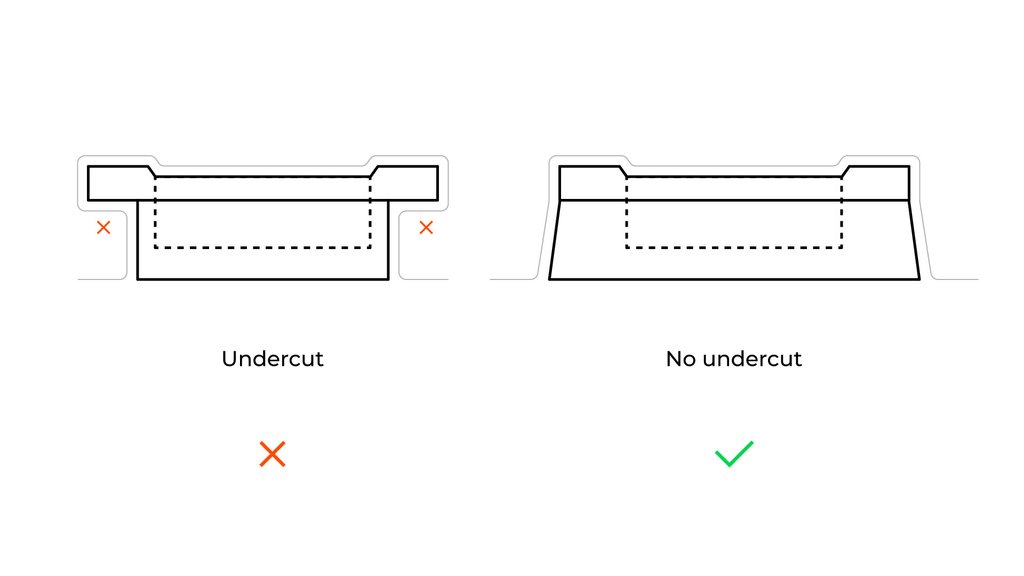

No undercuts:

This one is quite simple to understand. If you vacuum form a model that has ledges or overhangs, you won’t be able to remove the object once the plastic sheet cools down. Even the smallest ones could prove a hassle when trying to remove it and you might have to start again.

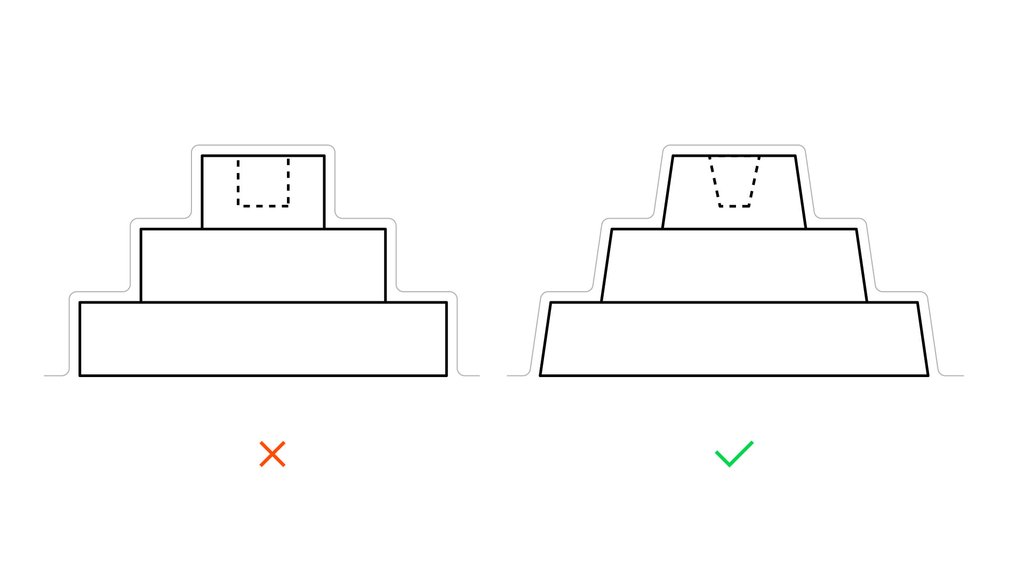

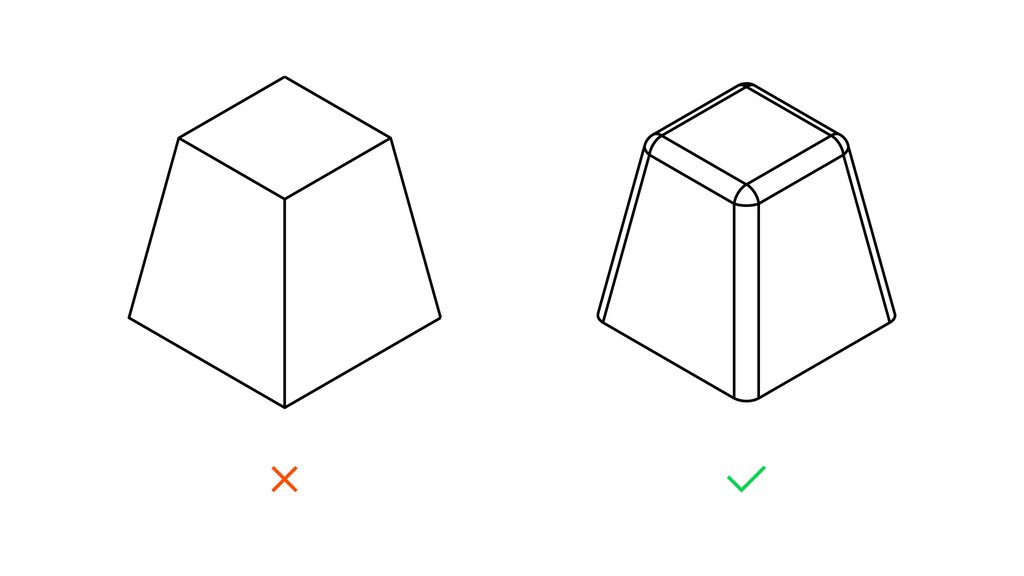

Add draft angles:

Draft angles are all about manufacturability. A draft angle is a slant that is applied to the faces of your model, and it helps when releasing the template from the plastic sheet. If you’re 3D printing objects to make moulds with, it’s recommended to add at least 1º of draft for every 2cm of height. Draft angles should be present in all the large faces of your model.

Draft angles also allow you to make bigger moulds as vertical walls can only be used for small details. Large faces with vertical walls can generate a vacuum, which means the part would get stuck to the plastic sheet.

Textures:

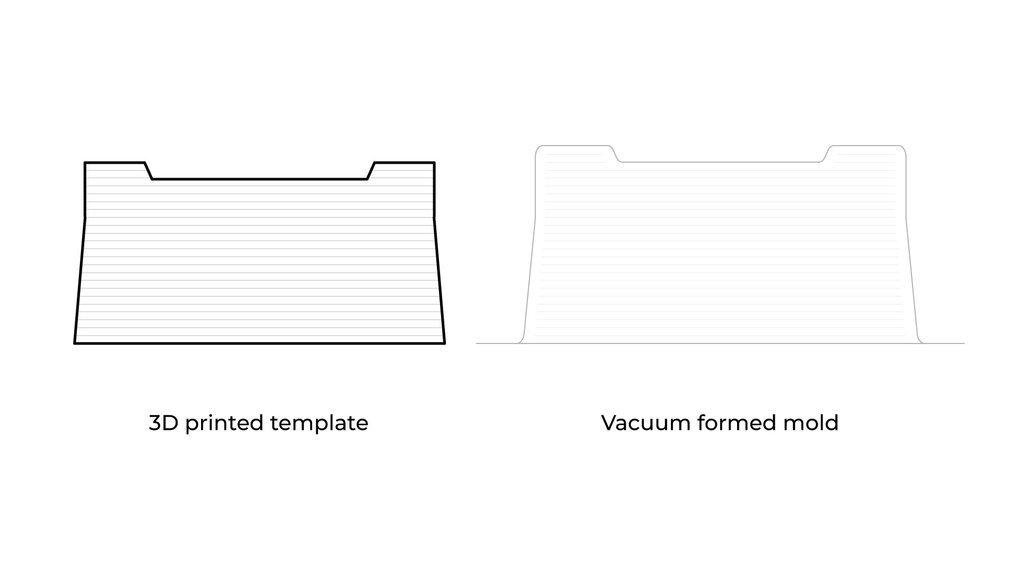

3D printed objects usually have a unique surface texture because of the printing process. Even though there are many materials that visually hide the layer lines, they’re still there and the FormBox is great at picking up textures.

If you want to have a smooth surface on your mould, the first thing you need to do is to 3D print using thin layers. 3D printing using 0.1mm layers offers a smooth surface. However, if you want a perfect surface, you will need to post-process the part. Using fillers and sanding is the easiest method, although it doesn’t work with small details. In those cases, sandblasting is a better option.

If you’re making moulds using other materials like wood, then make sure it's smooth would help the mould come out looking better. Unless of course, you want it to have a rough texture.

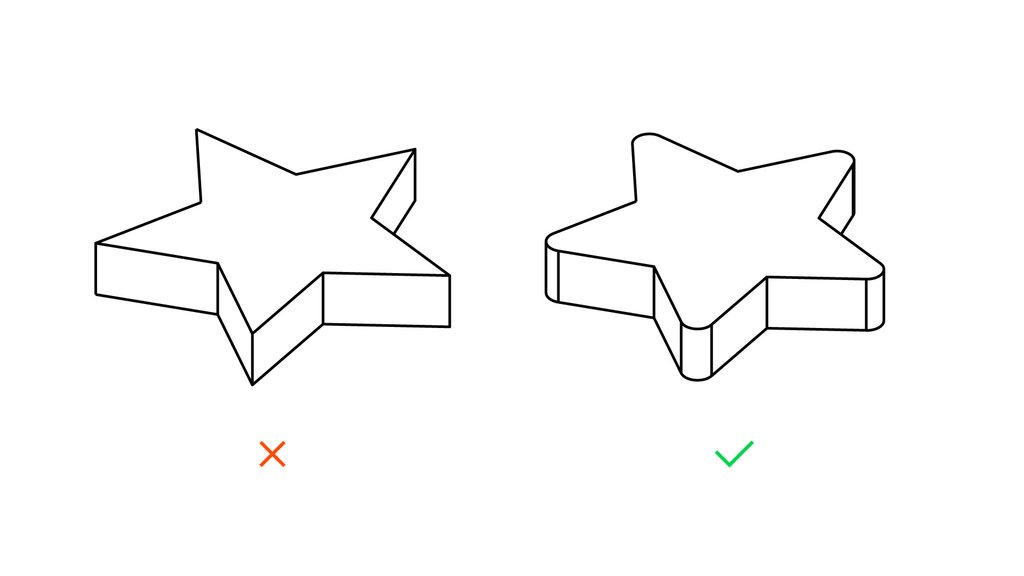

Avoid sharp angles:

Due to the manufacturing process, vacuum forming doesn’t always work with templates that have sharp angles (>90º). The main reason is that the plastic sheet may fold onto itself on sharp edges, reducing the mould quality.

For example, if you use a star-shaped object as a template, the points of the star may cause webbing as they’re quite sharp. On the other hand, a pentagon-shaped template or a star-shaped template with rounded corners would generate a high-quality mould as there are no sharp angles.

Round all corners:

In the injection moulding industry, it’s common to round the edges of the models. Rounding edges not only increases ergonomics but it also helps with releasing the part from the mould.

With a 2mm fillet you can make a big difference, reducing webbing and improving the mould’s surface finish.

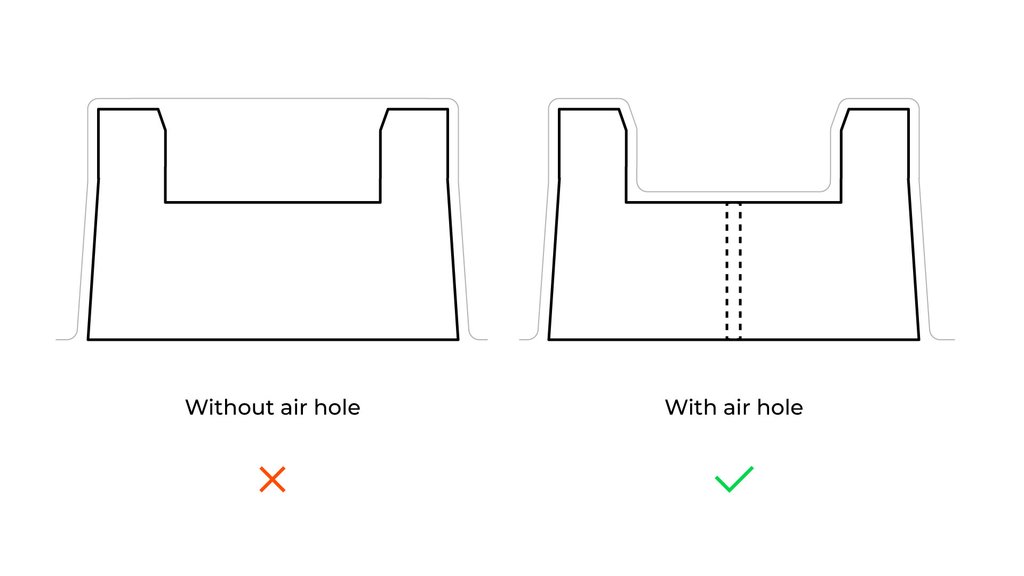

Add air holes:

The better the air flows, the more details the mould has. When the plastic sheet is deposited over the template, there’s a very small time window in which the sheet is hot enough and the air is moving. You want air to move as fast as possible, as that means the sheet will capture better details.

This is especially relevant if your design has parts where the air can get stuck. In those areas, it’s recommended to add small holes where the air can move. A 1mm hole may not even be visible in the mould, but it will greatly improve the mould quality.

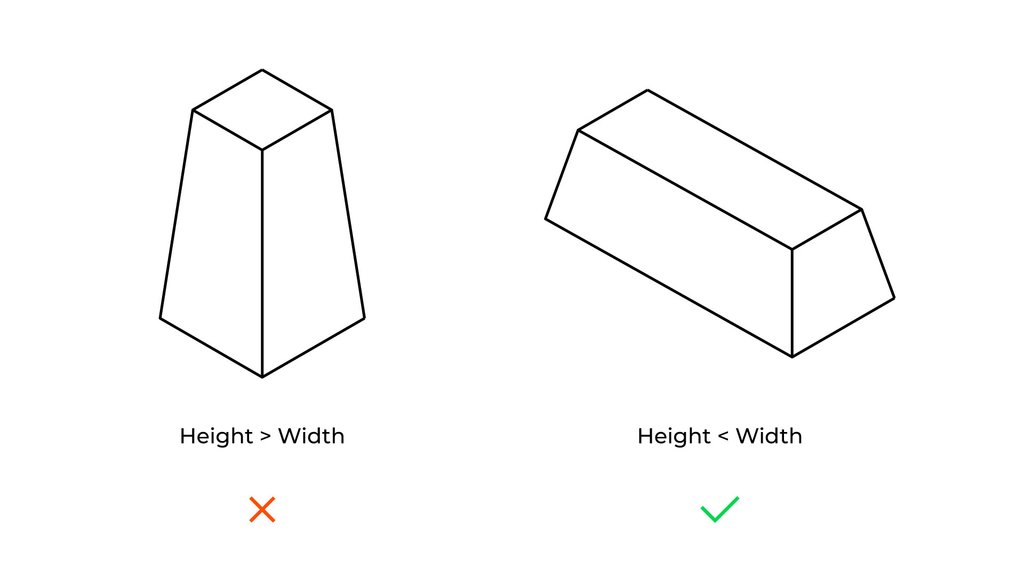

Hight vs Width:

The maximum mould size you can make with the FormBox is determined by the overall shape complexity. However, you should always remember that wide parts are easier to make than tall ones.

If you consider all the best practices, you will be able to make moulds of tall parts. In any case, try to use templates that are wider than taller or use generous draft angles to compensate.

Thats It!

This should cover everything you'll need to know to get started with your Mayku FormBox. These steps should hopefully make your manufacturing process easier and your products will come out more refined and ready for post production.